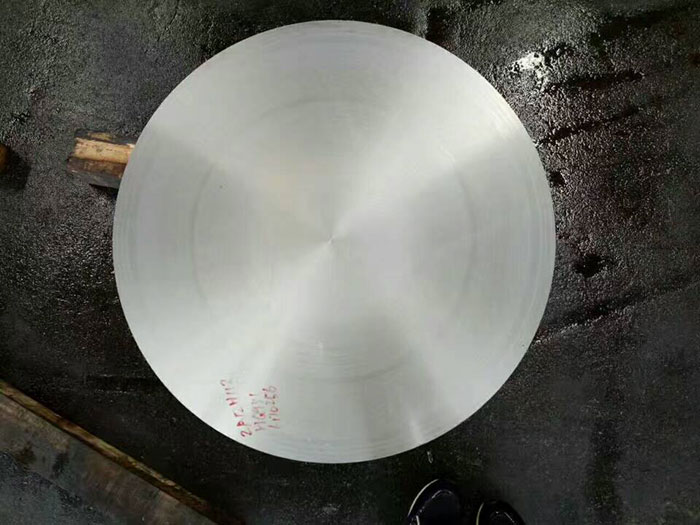

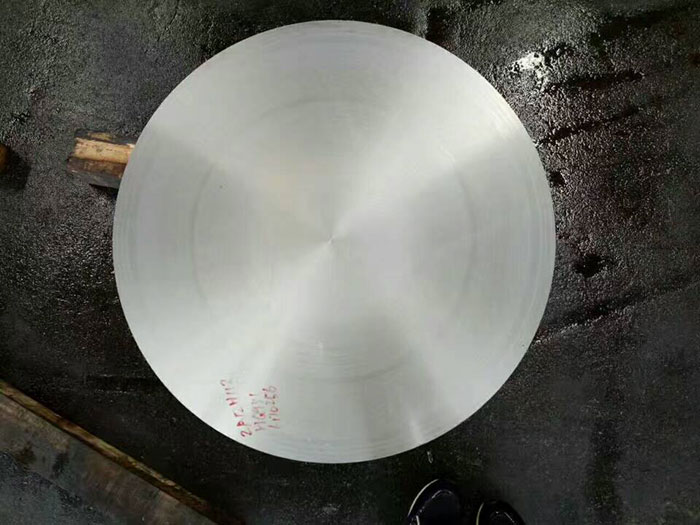

Introduction of Aerospace Parts Forgings

Henan Chalco can produceAerospace Parts Forgings, including fuselage parts: landing gear and its supporting beams, cabin door frames, wings, frames and other forgings. It can produce more than 90% of forgings on the fuselage.

As well as aero engines, engine forgings such as engine mounting joints, casings, turbine disks, shafts, blades, etc., can produce more than 90% of forgings for aircraft engines.

Introduction alloy of Aerospace Parts Forgings

7XXX series high strength alloys are proven materials for aerospace applications. With decades of high-level expertise in high-strength and ultra-high-strength aluminum alloys, our goal is to develop new alloys and optimize processes to ensure that the 7XXX series alloys with light weight potential are made in the automotive industry Greater contribution.

The Alloys of Aerospace Parts Forgings include:

7A04, 7B04, 7A09, 7075, 7049, 749A, 7050, 7A19, 7A10, etc.

Temper: O, F, H112, T3, T4, T5, T6, T62, T652, T73, T74, T7452, T852, etc.

Characteristics of Aerospace Parts Forgings

1. High strength heat treatable alloy.

2. Good mechanical properties and anodizing reaction.

3. Good toughness.

4. T7451 state has excellent resistance to stress corrosion cracking.

5. Good anti-stripping corrosion.

6. Lower quenching sensitivity.

The usage of Aerospace Parts Forgings

Aerospace Parts Forgings combines high toughness, high strength and excellent resistance to stress corrosion cracking, which makes it the material of choice for the aerospace industry. Main applications include: fuselage frames, bulkheads and wing skins, other uses include structural applications and marine components, military components, high-speed slewing bodies, mobile equipment, high-stress components

Henan Chalco can produceAerospace Parts Forgings, including fuselage parts: landing gear and its supporting beams, cabin door frames, wings, frames and other forgings. It can produce more than 90% of forgings on the fuselage.

As well as aero engines, engine forgings such as engine mounting joints, casings, turbine disks, shafts, blades, etc., can produce more than 90% of forgings for aircraft engines.

Introduction alloy of Aerospace Parts Forgings

7XXX series high strength alloys are proven materials for aerospace applications. With decades of high-level expertise in high-strength and ultra-high-strength aluminum alloys, our goal is to develop new alloys and optimize processes to ensure that the 7XXX series alloys with light weight potential are made in the automotive industry Greater contribution.

The Alloys of Aerospace Parts Forgings include:

7A04, 7B04, 7A09, 7075, 7049, 749A, 7050, 7A19, 7A10, etc.

Temper: O, F, H112, T3, T4, T5, T6, T62, T652, T73, T74, T7452, T852, etc.

Characteristics of Aerospace Parts Forgings

1. High strength heat treatable alloy.

2. Good mechanical properties and anodizing reaction.

3. Good toughness.

4. T7451 state has excellent resistance to stress corrosion cracking.

5. Good anti-stripping corrosion.

6. Lower quenching sensitivity.

The usage of Aerospace Parts Forgings

Aerospace Parts Forgings combines high toughness, high strength and excellent resistance to stress corrosion cracking, which makes it the material of choice for the aerospace industry. Main applications include: fuselage frames, bulkheads and wing skins, other uses include structural applications and marine components, military components, high-speed slewing bodies, mobile equipment, high-stress components